Inspired by nfeske Trackball smoothness I decided I wanted to modify my open trackball to improve the smoothness. However instead of modifying the one that came with my reform I wanted to model and 3d print my own.

The original trackball cup from the reform is open source, however it was modeled in Autodesk Fusion 360, and I wanted to work with something open and easily tweakble instead. So instead I took measurements of my original trackball and modeled a work-alike in OpenSCAD. Into this model I increased the gap around the ball to the cup, as well as made pockets for 3x 2.5mm chrome steel ball (bearings) to sit in. My model and code can be found here:

After the first design I determined that the pockets for the bearings were too small as a result of inaccuracies in the print, and tollerances. The second design added 0.3mm to the diameter of the holes to allow for an easy fit. However I found that the placement of the balls and the wider cup design had an unintended side effect. The trackball could be pressed from the side and “ride up” the balls, as well if the laptop was used at an angle it would also do so.

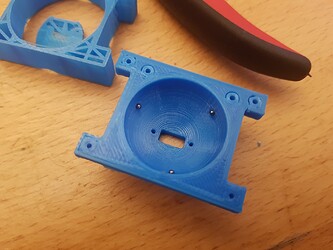

For the third and current attempt I moved the balls up much higher in the cup, resulting in a 22 degree contact angle with the ball, rather than my original 45 degrees. I also reduced the 0.3mm tollerance diameter down to 0.25mm.

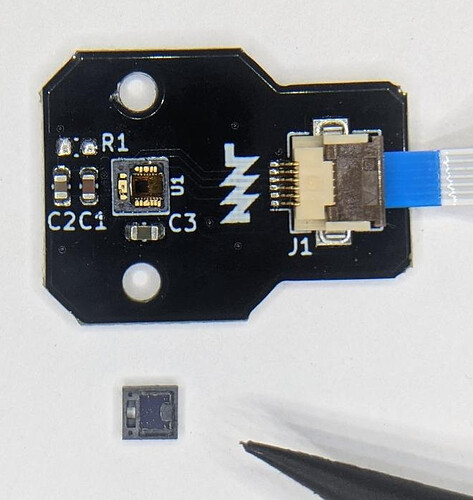

The chrome steel ball bearings are super glued into place and care is taken not to get any glue on the contact surface, though if you do it can be simply scratched off. I used 2.5mm GCr15 ball bearings from this seller High Quality Precision Steel Chrome Ball Ball Bearing Smooth Ball Dia 1mm-30mm | eBay though any similar 2.5mm bearing should work, be it chrome steel, ruby, or glass. The OpenSCAD file is also adjustible to any size of ball bearing, though you may need to adjust the cup_diameter inward for smaller ones so they’re supported more.

In my opinion this new model creates a significantly smoother trackball experience akin to some older model trackballs I have. It’s not as smooth as my Logitech trackballs but I put that down mainly to the ball material (delrin) and lack of weight as it has a bit of a scratchy sound. The Logitech mice also use ruby bearings which may be smoother. It’s still miles smoother than the stock design, and should hopefully have less issues with dust buildup over time.

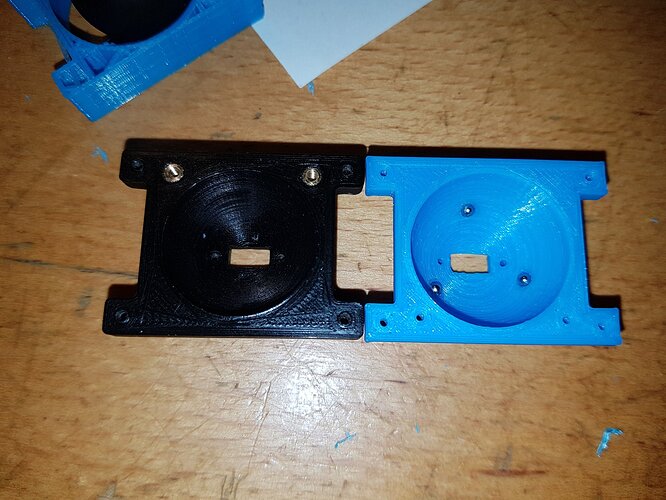

First revision of the model with the low (45 degree contact) mounted bearings, next to stock:

One small difference is my model does not use threaded inserts for the top retaining ring mounting as I did not have any available, though there is an untested flag in the code to widen the holes to support them.

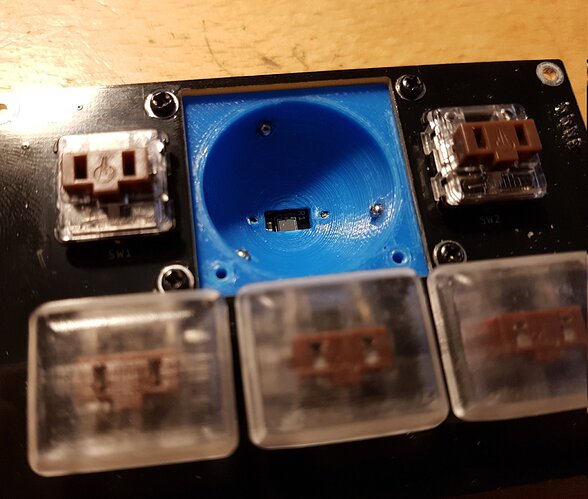

Current revision with the high contact angle: