Okay, it’s all fixed up!

Here are a few photos:

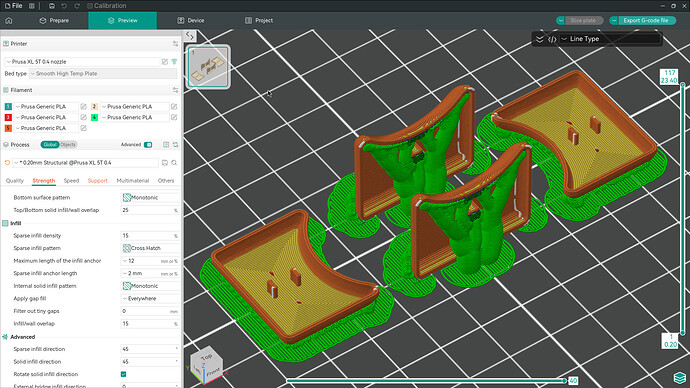

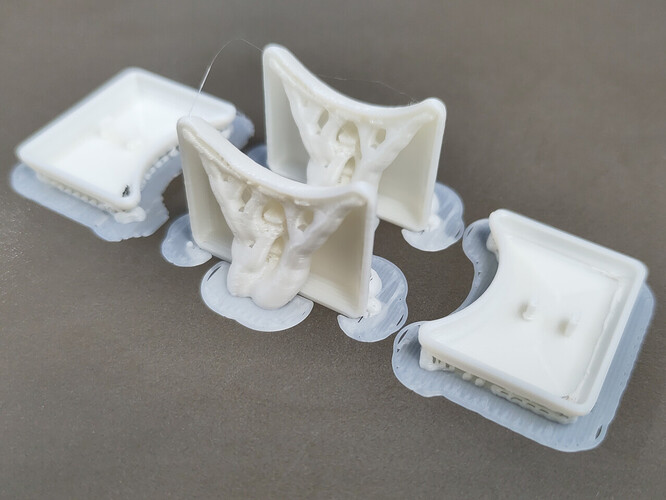

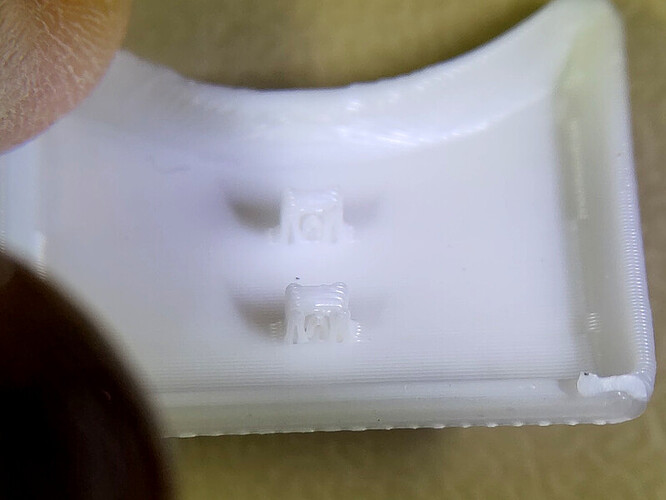

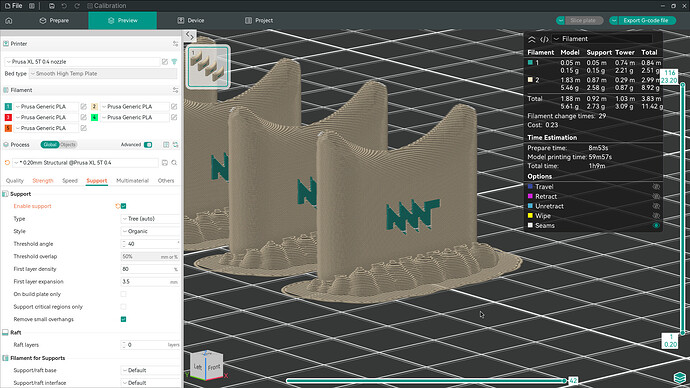

I printed two sets of key: one flat, one vertically, to compare the tabs and get a feel of how strong they would be depending on how the filament got layered up:

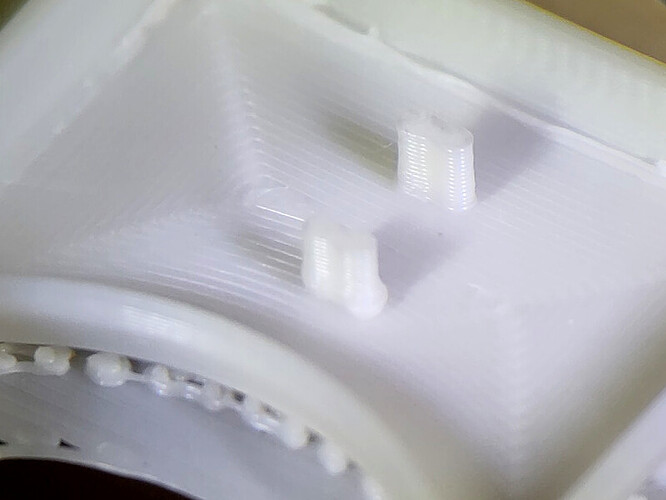

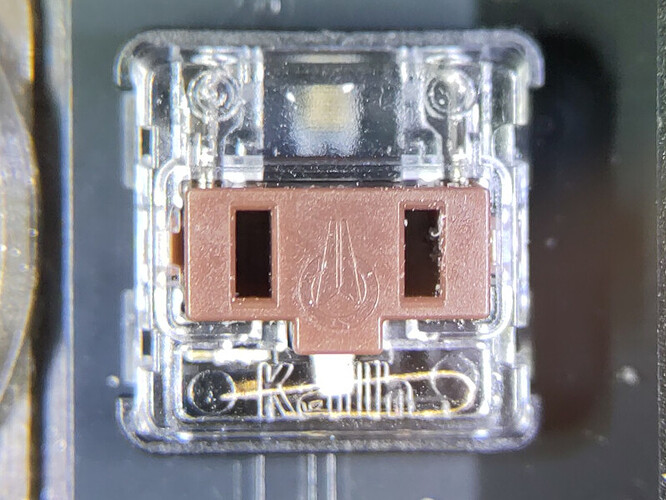

This is how the tabs look under the microscope, for the keycaps printed flat on the bed:

They are more or less dimensionally accurate but they still need some rework. They seem solid, but they’re just a bunch of narrow layers stuck together, so it’s not ideal.

And here, the tabs on the ones printed vertically:

They are not dimensionally accurate and they have these fillets at the root because they’re made of continuous hoops. But… they’re continuous hoops, so presumably more mechanically sound.

In the end, I bet on the latter and reworked the tabs to the correct dimensions with a needle file so they don’t get stuck inside the key’s notches.

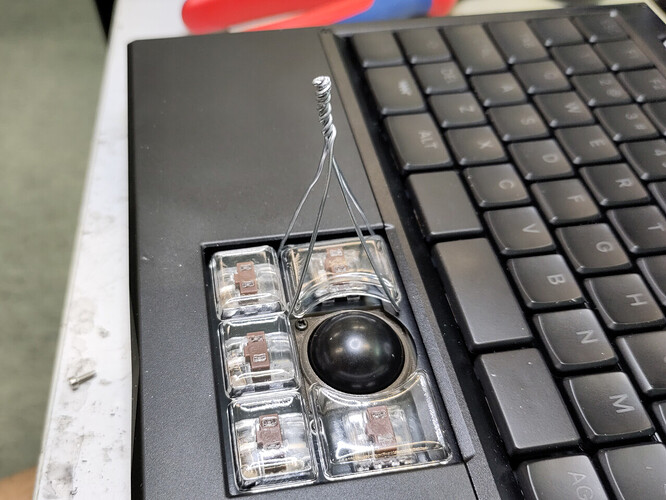

Then I removed the old keycaps, that still held on by one tab. But this time, I won’t be caught dead breaking another tab ever again by wrenching the keycaps out - on these resin keycaps or my PLA ones. So I made me a custom keycap puller out of chicken wire

It took me 10 minutes to make and it works really well!

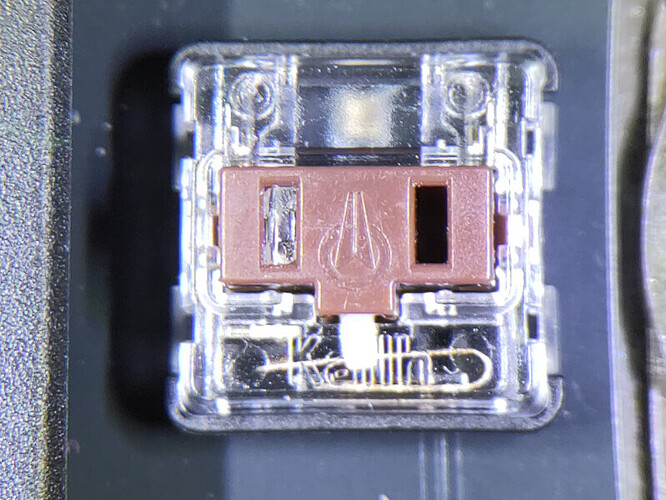

Then I got to work removing the broken tabs from the keys:

The hot needle trick didn’t work and I couldn’t get a thin blade in there for the life of me.

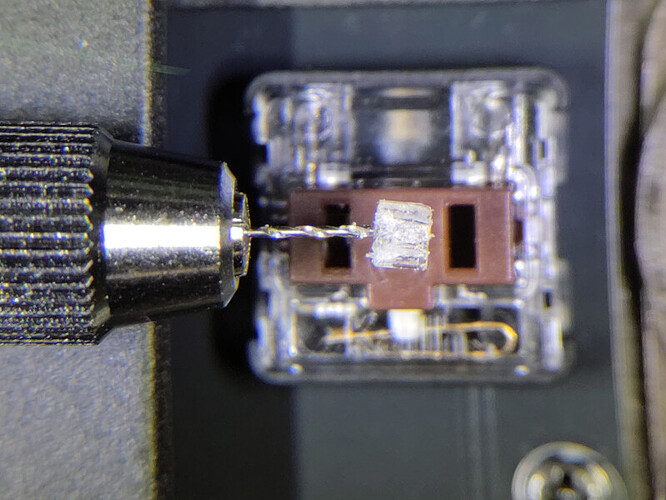

In the end, what worked was drilling half-way through the broken off tabs with a 0.5mm drillbit and a hand drillbit holder (commonly sold at hobby stores to work on scale models), then carefully pulling out the tab with the half-stuck drillbit.

In one case, I had to drill 3 holes to weaken it enough that it came out at the third drilling operation. In the other, it came out first time out.

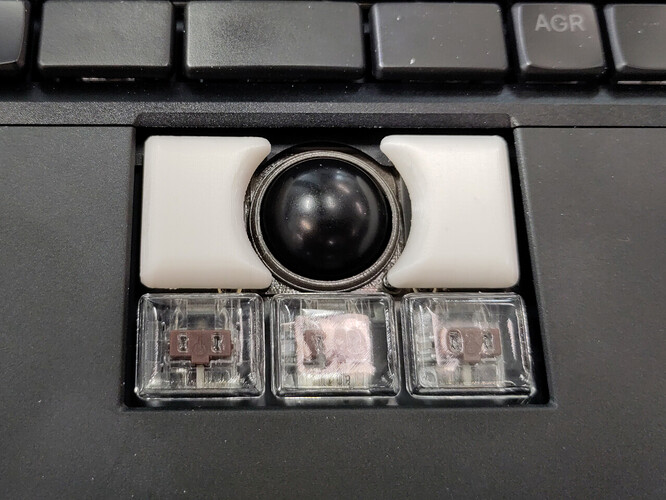

But crucially, came out they did eventually, and they left the keys totally unscathed:

Then I presented my new PLA keys, gingerly pushed them in, making sure they didn’t need to go in forcibly, and they slid right in with just a gentle amount of force. So I’m reasonably confident I’ll be able to get them out without drama, with the keycap puller, next time I have to get to the bottom of the trackball.

This is how it looks now:

Clearly not original  But I don’t care: it’ll remind me that, while not perfect, the beauty of this laptop is that you can repair it yourself. If something doesn’t work, be it software or hardware, YOU can fix it! That’s precious, and that’s why I don’t mind paying more for a quirky German laptop

But I don’t care: it’ll remind me that, while not perfect, the beauty of this laptop is that you can repair it yourself. If something doesn’t work, be it software or hardware, YOU can fix it! That’s precious, and that’s why I don’t mind paying more for a quirky German laptop

![]()