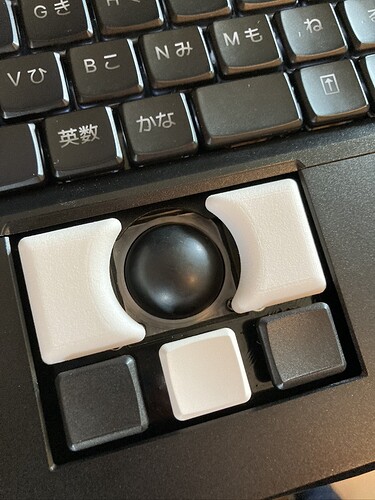

About an hour ago I dropped a battery on the two rightmost trackball buttons, snapping off both their legs in the switch. One leg in each switch snapped right at the top, so I was able to lift those out with a bit of tape. The other two were in pretty deep, and I was hesitant to put a heated needle into my switches for fear I’d warp the stems somehow and render them unusable.

–

PSA: I took the bottom off the Reform, removed the batteries, and took out the whole trackball module after losing the little metal stabilizer from one of the switches somewhere inside the machine. Don’t be like me. Take out the batteries and the trackball module first.

–

To retrieve the other two legs from the stems, I grabbed my curved-tip tweezers and tried working them under the tabs on the sides of the trackpad switches, one at a time. (I found freeing the screen-side right-hand tab, followed by the user-side right-hand tab, easiest. The screen-side tabs are able to pull away from the PCB a bit more, and the right-hand tabs don’t have a trackball in the way.) I managed to open the switches this way, which allowed me to remove the stems. I took a bit of gaffer’s tape (nothing special about it; it was just what I had on hand), placed it sticky-side up on my desk, put a stem upside-down against it, and then pressed a thumbtack into its back where I imagined it would line up with the socket containing the broken leg. (There happened to be a small, faint circle from the manufacturing process in exactly the place I needed to push on both my switches.)

The thumbtack was able to push both leg pieces against the tape enough that I was then able to lift them out. After that I just put the switches back together. Next up: printing some new keycaps with my FDM printer! Open hardware for the win.

Edit: The legs on the keycaps from the FDM printer fit well (snugly, even), but they snapped right off when I tried removing the keycap. Left enough protruding that I was able to pull them out with tweezers, fortunately.

Edit 2: To avoid having to use supports, I’d printed the replacement keycap legs-up, with left the layers running perpendicular to the legs. @ruff’s concerns about interlayer adhesion were spot-on. I turned on supports and tried printing it in the model’s original orientation, and the resulting legs are much stronger. At least as strong as the originals. The look is rougher, of course, but I’m happy with 'em.

Used PLA for all of 'em.